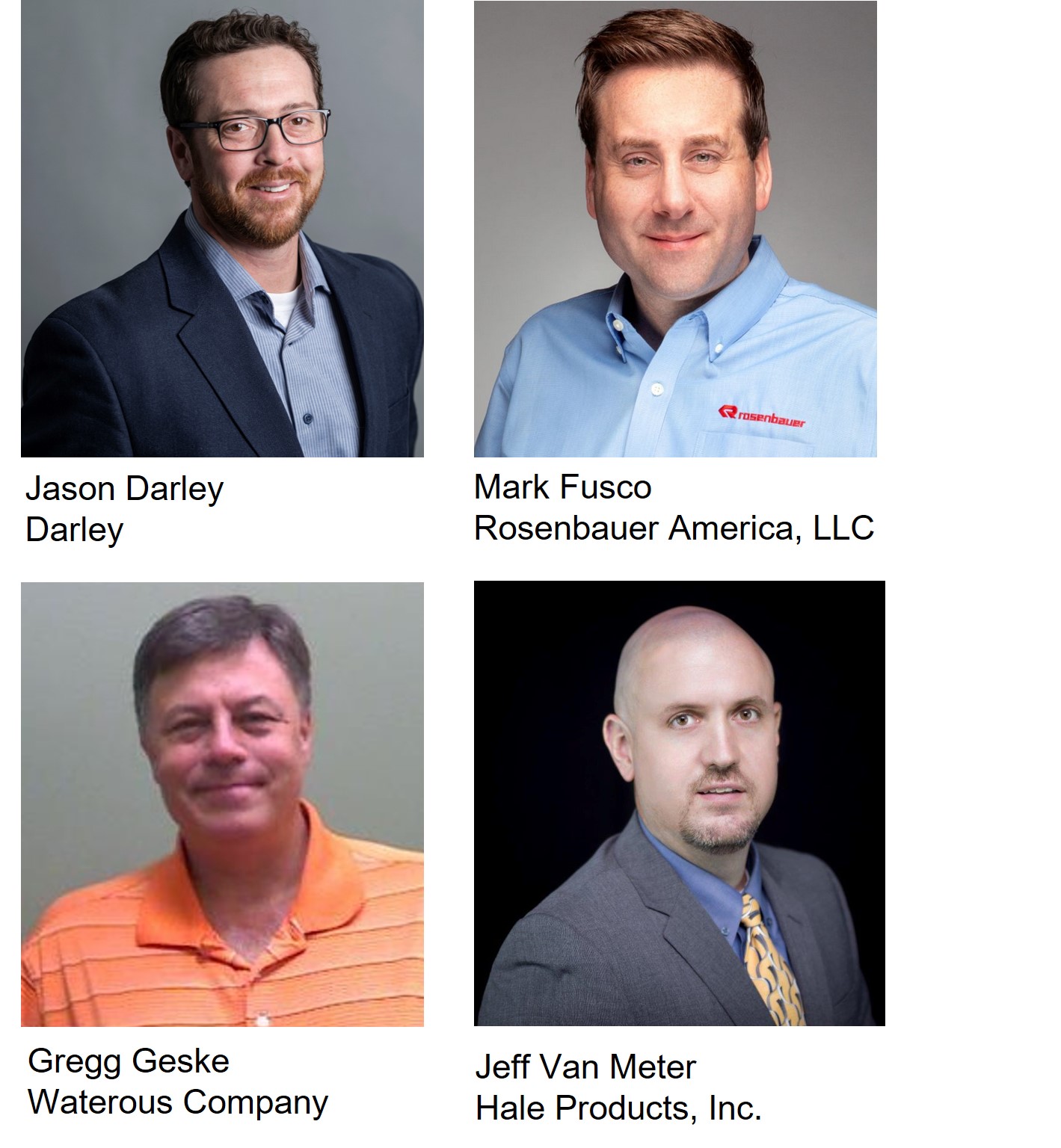

The most significant alterations and modifications of the centrifugal water pumps used in the fire service in the past 10 to 15 years were implemented to accommodate the envelope size of the pump necessitated by Environmental Protection Agency (EPA) initiatives. Other revisions were associated with automation and electrification.

Fire departments, during this time, have continued to face increasing and changing dynamics resulting from growing urban centers, firefighter turnover, and green mandates, among other factors. FAMA member companies have developed new pump technologies to address these emerging challenges and have dedicated various resources to acquaint you with innovative solutions for your department’s specific needs.

AUTOMATION AND ELECTRIFICATION

Traditionally, the fire service has used the apparatus engine to power the fire pump. The electrification of fire apparatus has opened new avenues for doing this. In some situations, the propulsion system is now disconnected from the pumping system and different power sources can be used for each system. Electrification and automation should not change the capacity of the pump you need.

FAMA member pump manufacturers are ready for the electrification of the fire apparatus. There are minor differences between driving a pump from a diesel engine, an electric motor, or both. Pump manufacturers are working with apparatus manufacturers to help ensure the fire pump runs as efficiently as possible to conserve battery power. The instant torque provided by electric motors turns on the system instantaneously and eliminates the need for “idling.” The attack crew’s call for water turns on the fire pump.

Automation in the apparatus electrical system has been present for years. Load managers, for example, choose the circuits that will stay active if high electric loads compromise the output of the apparatus. Expanding automation to the pumping system eliminates manual steps at the pump panel, increasing focus and attention on the fireground.

Changes are also evident in system integration. In the past, products from various manufacturers traditionally were used to meet a department’s pumping solution. The individual components did not always integrate well enough to create a cohesive pumping system. The development of pumping systems that help to automate the fireground has changed that, resulting in a safer and more efficient process.

FAMA member companies offer options for meeting your department’s needs and provide optimum guidance in selecting the best pump for your applications. Keeping abreast of the marketplace and the industry, they work diligently to make you aware of the most recent pump technology developments and solutions for your needs.

TYPES OF PUMPS

The types of fire pumps commonly used in the fire industry are single-stage, two-stage, three-stage, four stage, and multi-pumps. A pump may be single-eye impeller (end suction) or dual-eye impeller (full bodied).

Single-eye impeller (end suction) pump. Water from the intake flows directly into the impeller’s single eye. The rotation of the impeller pressurizes the water. Local conditions and elevations may slow the time it takes an end-suction pump to draft. It has a smaller pump body and pump interior (volute) than the dual-eye impeller–less water is in the pump to absorb heat when operating at a low flow. The impeller flows near the pump’s rated capacity. If the water is not adequately recirculated when operating at a low flow, recirculation cavitation or an overheat condition can occur.

Dual-eye impeller (full-body) pump. Water enters the pump through the intake manifolding, and the inbound water stream is split. Half of the water flows to the front impeller eye; the other half flows to the rear impeller eye. The rotation of the impeller pressurizes the water. Dual-eye impellers can vacate air in the pump body more quickly than single-eye impellers, allowing for a quicker vacuum and draft.

STANDARDS

Fire industry pumps meet the “10-foot lift at 2,000 feet elevation” specification in National Fire Protection Association (NFPA) 1911, Standard for the Inspection, Maintenance, Testing, and Retirement of In-Service Emergency Vehicles.1 They are engineered, manufactured, and tested to these standards.

WHAT KIND OF PUMP DO YOU NEED?

How do you determine the type of fire pump you need? First, assess the needs of your department: What are the most common types of fires to which your department responds? Does your jurisdiction have occupancies that present the potential for other types of fires that may occur rarely but will often challenge your department’s resources? Focus on gallons-per-minute (gpm) and pounds-per-square-inch (psi) requirements, how the pump is powered and used, and the overall construction of the fire apparatus, for example.

Learn the types of options available for normal-pressure and high-pressure pumps and the applications each type of unit (traditional pumper, urban interface unit, for example) is designed to serve.

Additional Points to Consider

When considering additions, such as a butterfly valve, to the suction inlets, discuss the capability aspect with the engineering team of the manufacturer of the original equipment. Adding a butterfly valve on an end-suction pump may limit an application’s capability.

When elevation may be a factor (drafting), ask about the pump’s elevation lift capability. As elevation increases, less atmospheric pressure bears down on the water source, which can affect the pump’s drafting capabilities. In recent years, the need has arisen for pumps to accommodate the higher pressure needed for high rises, which continue to be built taller and taller. FAMA member companies and the fire industry have developed fire pumps and accessories for this application that can withstand the higher pressures needed for the gpm and psi requirements.

MAINTENANCE

Fire pumps are maintained and tested to manufacturers’ recommendations and according to the guidelines contained in NFPA 1911. Every pump manufacture has a list for maintenance intervals; many of them are correlated with the annual recertification process to make it easier on maintenance personnel.

TRENDS AND THE FUTURE

In traditional apparatus, customers are focusing on the cost of ownership of the unit over its lifetime. Departments continue to consider the maintenance requirements in conjunction with the availability of parts when planning a purchase.

EPA changes that affect the drive train have the “potential” to impact the fire pump / suppression system, especially the space available for the system. FAMA member companies serve on standards technical committees and other bodies that oversee revisions needed to adjust to the ever-changing work environment and safety and health issues. These companies closely follow how the potential changes will impact the suppression systems engineered into fire apparatus and, therefore, cost. Often, complying with the revisions necessitates additional components and attention.

Electrification will continue to drive evolution in the pumping world as the fire industry embraces electric or hybrid vehicles. With electrification, all options will continue to evolve– pump efficiency, weight, packaging, and drive methods. Some of the other issues to be determined relative to electric vehicles include the following: How will the truck be recharged? Will it be used only for initial attack?

Automation can be as simple as opening the tank to pump, to ensure water is available for the pump, or as complicated as having a system that performs many of the engineer’s usual tasks.

FAMA member companies make it a priority to keep the fire industry current on any pending changes that will affect them positively or negatively. We work closely with fire departments to help them meet their needs as efficiently and as economically as possible. That means that we are constantly innovating–whether for a customized solution for a specific vehicle or a product that follows industry trends and applications used throughout the marketplace. Our goal is to inform and empower you to make the best long-term decisions that will support your departments’ objectives.

FAMA member pump manufacturers are a primary resource for the fire industry. We are available to consult and engage with you to address your questions and concerns. An immediate resource for pump information is the FAMA Buyer’s Guide on Pumps available at

https://www.fama.org/wp-content/uploads/2018/01/TC024-Buyers-Guide-Water-Pumps-180326-1.pdf and https://www.fama.org/fire-service-resources-list/?search=pumps/.

FAMA is committed to the manufacture and sale of safe, efficient emergency response vehicles and equipment. FAMA urges fire departments to evaluate the full range of safety features offered by its member companies.

FAMA Forum creative content is contributed by unpaid volunteer authors. Any opinions expressed herein are exclusively those of the author and are not intended to represent the views of FAMA or its member companies.