Introduction

Vehicle suspension systems are an important factor in the ride quality, stability, and ongoing maintenance of an apparatus. When developing specifications for the rear suspension on a fire apparatus, consideration should be given to handling, ride quality, chassis/equipment protection, initial cost, capacity, and total cost of ownership.

Contents

Overview

Ride quality is a function of wheel travel and the spring rate of the suspension. Ride quality is not only a benefit for vehicle occupants but provides protection for the vehicle and the equipment it carries. The amount of allowable wheel travel is determined by vehicle packaging and the spring rate of the system.

Roll stiffness is a key consideration for vehicle design due to the high center of gravity that fire apparatus typically exhibits. There is a balance, and sometimes a tradeoff, between roll stiffness, ride quality, and off-road traction. Lower roll stiffness results in better off-road mobility but may introduce a feeling of instability in a high center of gravity apparatus. Higher roll stiffness may result in lower ride quality but will offer better stability during high-speed maneuvers.

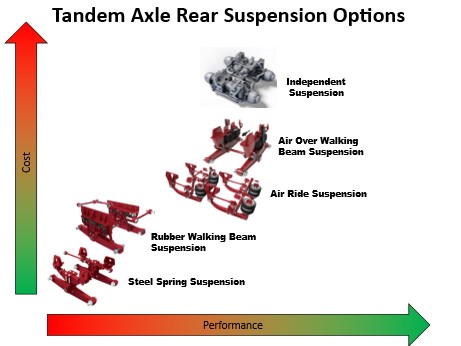

There are 4 basic rear suspension types: multi-leaf spring, rubber, air ride, and independent. This guide will provide a description, pros and cons, operating environment considerations, and capacity ranges for each suspension type.

Rear suspensions can be specified as a single axle or tandem axle configurations. For custom fire trucks, single axle rear suspensions cover capacities from 20,000lbs up to 35,000lbs. The fire truck industry has been pushing the rear single axle capacities higher to allow for shorter wheelbase to improve maneuverability over what can be achieved with a tandem configuration. The tandem axle suspensions cover capacities from 40,000lbs up to 70,000lbs. There are some different options for the tandem configurations so this guide will try and cover both.

Higher cost suspensions often result in better operating characteristics such as ride quality and lower cost of maintenance. This guide will provide a description, pros and cons, and operating environment considerations for the typical types of suspensions used in the fire truck industry.

Steel Spring Suspension – Single Axle Configuration

This system is currently the most common in fire apparatus. A steel multi-leaf spring suspension is a stack of individual leaf springs between the vehicle frame rails and the axle. Spring suspensions are available for both single axle and tandem axle applications. The spring packs are responsible for supporting the vertical load as well as providing roll stability which creates a compromise between ride quality, traction, and roll stability.

PROS OF SPRING

- Low initial cost

- Good roll stability

- Readily available parts

- Good serviceability

CONS OF SPRING

- Poor ride quality

- Reduced equipment protection

- Load affects ride height and ride quality

- Poor off-road mobility and traction

- Requires load balancing to prevent vehicle lean

- Potential for drive line vibration during aggressive driving

- High amounts of friction between leaves resulting in wear and corrosion resulting in lower overall durability

- Heavier than other systems

Air Ride Suspension – Single & Tandem Axle Configuration (Torque Reactive)

Torque Reactive Air ride suspensions are available in both single and tandem axle configurations. These systems use an air spring to isolate road inputs and height control valves to maintain a constant ride height. Torque reactive air ride suspensions are considered entry level air rides. Torque reactive air suspensions connect solid to the axle and do not use a longitudinal upper torque rod. This causes the axle to swing through an arc. The suspension geometry will cause the trucks body to rise during acceleration and squat during braking events.

PROS OF AIR RIDE (TORQUE REACTIVE)

- Good ride quality

- Good equipment protection

- Good roll stability

- Maintains constant ride height

- Similar ride quality when both loaded and empty

- Built in side to side leveling – no lean

- Easier to service due to lighter weight air springs

CONS OF AIR RIDE (TORQUE REACTIVE)

- Poor off-road mobility and traction.

- Can be more expensive than multi-leaf spring and rubber suspensions

- Axle connection hardware requires preventative maintenance

- Will experience body rise/fall during acceleration/braking

- Potential for drive line vibration during aggressive driving

- Airbags are susceptible to damage or punctures

- Loss of system air pressure may require reduced speed due to driveline misalignment

Air Ride Suspension – Single & Tandem Axle Configuration (Non-Torque Reactive)

Non-Torque Reactive Air Ride Suspensions are available in both single and tandem axle configurations. These systems use an air spring to isolate road inputs and height control valves to maintain a constant ride height. Non-Torque Reactive Air Ride Suspensions are considered the premium level air ride. Non-Torque Reactive Air Suspensions have an added pivot point at the axle connection and an added longitudinal upper torque rod(s). This allows the axle to move almost straight up and down and better controls the acceleration and brake toque, so body does not change height during those events. This keeps the drive line in its optimal geometry.

PROS OF AIR RIDE

- Best ride quality

- Best equipment protection

- Good roll stability

- Similar ride quality when both loaded and empty

- Maintains constant ride height

- No body rise/fall during acceleration/brake events

- Built-in side to side leveling – no lean

- Easier to service due to lighter weight air springs

CONS OF AIR RIDE

- Poor off-road mobility and traction.

- Can be more expensive than multi-leaf spring, rubber, and torque reactive air suspensions

- Airbags are susceptible to damage or punctures

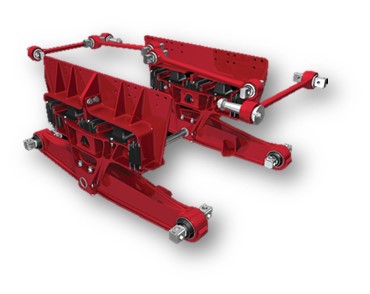

Independent Rear Drive Suspension – Single & Tandem Axle Configuration

Independent Rear Drive Suspensions are available in both single and tandem axle configurations. This system uses steel coil springs to isolate road inputs.

PROS OF INDEPENDENT REAR DRIVE SUSPENSION

- Good ride quality

- Good equipment protection

- Good roll stability

- Best off-road mobility and traction

- Improved Maneuverability if upgraded to mechanical rear steer

- Good durability

CONS OF INDEPENDENT REAR DRIVE SUSPENSION

- High cost

- Load affects ride height and ride quality

- Requires load balancing to prevent vehicle lean

- High weight

- Complex and additional wear points

- Only available at one fire apparatus manufacturer

Rubber Suspension – Tandem Axle Configuration

As the name implies, rubber is used to provide the “spring” between the axle and frame to isolate road inputs. Differing rubber hardness, or durometer, can be used to achieve the desired weight capacity and ride quality. The rubber springs are responsible for supporting the vertical load as well as providing roll stability which creates a compromise between ride quality and roll stability.

PROS OF RUBBER SUSPENSION

- Lighter weight than multi-leaf spring walking beams

- High roll stability

- Walking beam suspensions* provide good off-road mobility and traction

- Better corrosion protection vs walking beams using multi-leaf spring pack

CONS OF RUBBER SUSPENSION

- Poor ride quality

- Reduced equipment protection

- Load affects ride height and ride quality

- Requires load balancing to prevent vehicle lean

- Higher initial cost than multi-leaf spring walking beam

- Weight sensitivity (loaded vs. unloaded)

- More difficult to adjust for lean or ride height

* walking beam suspension is used to refer to a type of tandem suspension system that joins the front and rear drive axles with a rigid beam that pivots in the center. This allows each side to load balance and to articulate over uneven terrain keeping all four tire sets in contact with the ground.

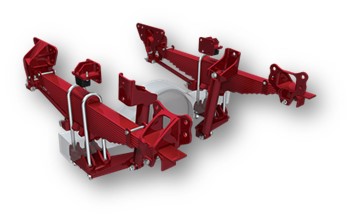

Air Over Walking Beam Suspension – Tandem Axle Configuration

The Air Over Walking Beam Air Ride suspension has a Non-Torque Reactive Air Suspension on top of the walking beam to optimize the relationship of ride quality, roll stability, and off-road mobility and traction. These systems use an air spring to isolate road inputs and height control valves to maintain a constant ride height. Air springs have internal rubber up stops that allow the system to become a rubber ride if system air pressure is lost so mission can be completed.

PROS OF AIR OVER WALKING BEAM SUSPENSION

- Good ride quality

- Good equipment protection

- Good roll stability

- Similar ride quality when both loaded and empty

- Walking beam suspensions provide good off-road mobility and traction

- Maintains constant ride height

- Built-in side to side leveling – no lean

- Easier to service due to lighter weight air springs

- Air springs are well protected due to being mounted above waking beam

CONS OF AIR OVER WALKING BEAM SUSPENSION

- More expensive than spring and rubber and torque reactive air suspensions

- High weight

- Airbags are susceptible to damage or punctures

Suspension Capacity

Departments should select the correct capacity rated products. Selecting higher capacity ratings does not increase vehicle durability, it can decrease the life of chassis/body/equipment. It can also decrease ride quality resulting in driver fatigue, lower resistance to rollover, and negatively impact vehicle handling.

Suspension capacities for single rear axles range from 20,000 to 35,000 pounds and for tandem rear axles from 40,000 to 70,000 pounds overall. Single rear axles typically use multi-leaf spring or air ride suspensions while tandem rear axles can use multi-leaf spring, rubber, or air ride. A high percentage of Aerial Trucks are now using air ride to improve ride quality and equipment protection. The trend for using air ride on single axle rear suspensions is also on the rise in the fire truck industry.

Other Considerations

Departments should consider the most common driving routes – city driving may result in higher vibrations due to road quality. Spring suspensions can typically transmit up to 50% more vibration to the apparatus compared to an air ride suspension.

Departments in northern environments where salts are applied, may benefit from selecting the more corrosion resistant rubber suspensions or air ride suspensions. The reason for this is that the leafs in a multi-leaf spring suspension can develop rust which increases the resistance to movement and can lower ride quality over time. Because there is relative motion between leafs, it is not possible to coat the individual leafs to prevent rust.

Summary

While initial cost of ownership may be higher for certain systems, departments should consider overall total cost of ownership which includes maintenance, ease of service, and wear and tear from reduced ride quality. With the inclusion of more sensitive electronic equipment, reduction in vibration becomes even more important.