FAMA BUYER’S GUIDE TC052 ELECTRONIC PRESSURE GOVERNORS (EPGs)

Prepared by the FAMA Electrical Subcommittee

This guide does not endorse any manufacturer or product

Contents

Introduction

Since the early 1990’s, electronic pressure governors (EPGs) have been used extensively on fire apparatus for controlling engine speed and associated pump pressure to facilitate accurate and consistent discharge line pressure. The purpose of this guide is to describe the various types of EPGs available for fire apparatus and to offer considerations for selecting the right EPG for your application.

There are a variety of commercially available EPGs to address the unique challenges associated with various fire-fighting scenarios. Differences in features, functionality and engine compatibility should be considered in selecting the right product to support your needs and to optimize your standard fire ground operating procedures.

Overview

Before the advent of EPGs, a combination of manual engine controls, mechanical gauges and mechanical discharge relief valves were utilized to control engine speed and monitor discharge line pressure. While manual throttle controls and mechanical discharge relief valves are still commonly used, the introduction of EPGs has allowed for quicker response to changes in pump pressure and thereby, smoother performance when opening and closing various discharge lines. In some cases, particularly when flowing large volumes of water, the EPG and mechanical relief valve can be used in combination to optimize pump performance.

How They Work

The pressure governor receives a signal from a pressure transducer mounted on the discharge side of the pump. As the transducer senses a change in pressure, the pressure governor sends a signal to the Engine Control Module (ECM) to increase or decrease engine speed to maintain the desired discharge pressure.

Common Types of Electronic Pressure Governors (EPGs)

The original pressure governors introduced into the fire market were designed to support mechanically controlled diesel engines. These devices were heavy solenoid operated governors installed by the fire apparatus manufacturer onto each engine. Linkages from the governor to the engine throttle lever would be custom fit for each application.

The introduction of electronic engines in the early 2000’s led to the evolution of pressure governors utilizing analog control signals to control engine speed. Further evolution of diesel engine technology lead to the introduction of CAN (Controller Area Network) control, utilizing J1939 communication protocol. This dramatically improved engine response time to facilitate even smoother control of various changes in pump pressure. Every effort is made by suppliers of EPGs to work closely with engine manufacturers to stay current with ongoing changes in engine control technology. Each supplier offers a variety of pressure governor models to support engines of varying control types. In this guide, we will review some of the most commonly used pressure governors and their attributes.

Standard Features of EPGs

At a minimum, all commercially available EPGs include the following features:

- Models available to support a variety of the most commonly used diesel engines of various control types (analog or digital)

- Check and stop engine indicators

- RPM, oil pressure, coolant/transmission temperature and battery voltage indicators

- Audible and visual warning indicators

- Pressure and RPM presets for ease of achieving desired operating parameters

- Programmable settings to optimize performance with various engines, transmissions and fire pumps

- Password protected menus to adjust for various vehicle related parameters, calibrations, warning and alarm values

- Separate menus for OEM, service and end user access with appropriate restrictions for each level

- Advanced parameters to adjust for interruptions in water flow or cavitation

Additional Features of EPGs

In addition to the features listed above, some EPG models are available with the following enhanced features:

- Master intake and discharge pressure digital displays

- Can eliminate the need for large mechanical master gauges

- Expanded information display window

- Fuel consumption indication

- Rotary throttle control in place of push button increase/decrease controls

- Can be integrated into main display or remote for flexibility in mounting

- Full color display with enhanced graphics

- Allows for intuitive diagnostic capability

- Supports multiple language options

- Integrated wiring diagrams and troubleshooting guides

- “Target” pressure/RPM indicator

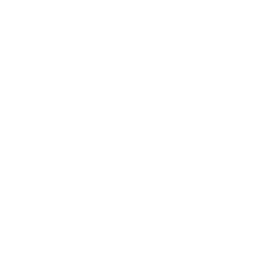

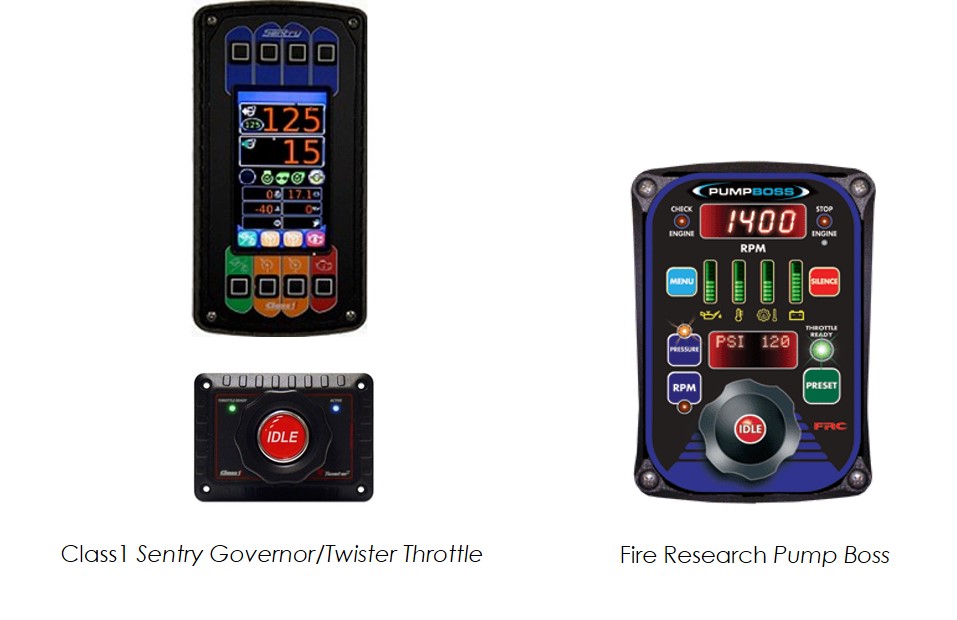

Examples of EPGs

- Both feature master intake and discharge pressure indicators

Examples of EPGs (Continued)

- Both feature ergonomic rotary throttle “knob” for easier increase/decrease control with gloved hand

Additional Resources

For more information regarding EPG options, please contact your apparatus manufacturer or FAMA electronics suppliers listed in the buyer’s guide at www.fama.org.