Introduction

This Buyer’s Guide covers the topic of Air Brakes on Fire Truck Apparatus and more specifically the choice between specifying Drum or Air Disc Brakes. Additionally, information is presented on the components that make up both braking systems and the steps necessary for maintenance. We believe this is important information to consider before your purchase so that you are fully informed before making your choice.

Contents

Brake Application Energy Selection

There are four possible ways to apply braking in a vehicle. The simplest means is mechanical linkages or cables. This was used on the very first automobiles and is still the method of choice for many parking brake applications.

The next is the use of hydraulics. This method is employed by most passenger cars and light trucks. The operator presses the brake pedal. The pedal lever is attached to a master cylinder that compresses hydraulic fluid. This fluid is transported to the brakes by lines and hoses. The pressurized fluid then moves a cylinder attached to the drum or disc brake actuator. The operator’s foot pressure is often supplemented by utilizing an electro-hydraulic pump or a vacuum diaphragm.

For large trucks and buses, the method of choice is the air brake system. The use of Air Brakes starts at a Class 7 Vehicle (GVW of 26,001 – 33,000 lbs) and Class 8 Vehicles (GVW of 33,001 – 80,000 lbs). It is possible to use Air Brakes on vehicles that weigh less than 26,001 lbs but only if the truck has an engine mounted air compressor. Air brakes are more practical for semi tractors where the air pressure can be coupled between the tractor and trailer without the mess, fluid cleanliness, and compatibility concerns associated with hydraulic brakes. Since this represents a large percentage of the heavy truck market it has been practical to use them on heavy straight trucks as well.

The final method of brake application is electrical actuation. This method is not approved for use in the US. Electrical control of air brake systems has been employed in Europe and may make its way into the US eventually.

Brake Type Selection – Disc vs Drum

Air brakes come in two versions, the disc brake and the drum brake configuration. Each has their own set of advantages and disadvantages, and the choice between them depends on various factors, including the specific application and requirements. While most automobiles and pickup trucks are all using disc brakes about half the on-highway commercial vehicles are still using Drum Brakes.

U.S. Department of Transportation Federal Motor Carrier Safety Administration published report FMCSA-RRT-19-005 in January 2021. The study was to develop information on stopping distance for platooning of Class 8 Tractor Trailers. The study did find that the average stopping distance for tractors with disc/disc (disc brakes on both front and rear axles) was shorter than a tractor with either drum/drum or disc/drum brakes. Likely the main reason that we have not seen a full conversion to air disc brakes for heavy trucks is their higher upfront cost. However, if braking performance and the total cost of ownership are important then you want to consider the upgrade.

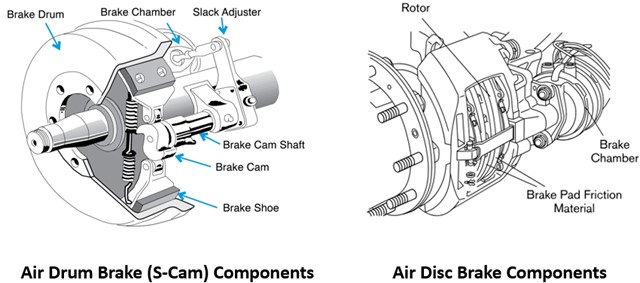

Heavy Brake Components

The illustrations below show the majority of the components that make up the drum brake and disc brake systems. Both are using an air chamber to supply the mechanical force. Inside each chamber is either a cylinder or a diaphragm that provides force to a push-rod. In drum brakes the push-rod acts on a lever attached to an “S” cam. When the cam rotates, it pushes against the ends of the brake shoes which in turn force them into the inside of the brake drum. Friction between the shoe and the drum slows the vehicle. In the case of the disc brake, the push-rod acts upon a lever that squeezes the brake pads onto the rotor. The friction between the pads and the disc slows the vehicle.

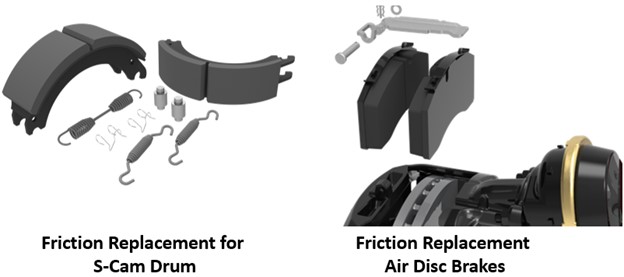

Servicability

When you look at the illustrations of the components that get replaced when replacing the friction material (brake pads) you can start to understand how much easier it will be to service the Air Disc Brakes versus the S-Cam Brakes.

Replacing the brake pads on an air disc brake is a relatively simple process. Following is a brief overview of the major steps:

- Remove the wheels

- Remove the retaining clips

- Remove the worn pad.

- Push the caliper all the way inward

- Inspect the guide pin boots for any damage that may require attention.

- Ensure that the caliper can slide freely and inspect the boots on the pistons of the caliper.

- Measure the rotor thickness to make sure it is within specifications

- Install the new pads and secure with new clips.

- Reassemble the wheels.

Replacing the friction on S-Cam Drum brakes is simple but does have a few more steps. Following is a brief overview of the major steps

- Remove the wheels

- Remove the brake drum.

- Remove the brake shoes by disconnecting the return springs and the hold-down springs and pins that secure the brake shoes.

- Inspect the other components for wear, damage or excess rust

- Check the wheel cylinder for leaks.

- Install new brake shoes ensure the correct orientation and secure them with the hold-down springs and pins

- Reconnect the return springs.

- Slide on the new brake drums and ensure they rotate freely

- Make the necessary brake adjustments to ensure proper contact between the brake shoes and drum.

- Reassemble the wheels.

S-Cam Drum Brake

Drum brakes were invented back in 1902 so they have been used for many decades. The S-Cam Brake system is well proven but does have the performance issue of brake fade. Brake fade means that the truck will lose stopping power durning long braking periods so the driver may have to push down harder on the brake pedal. It occurs because friction between the shoe friction material and drum creates heat. As the drum heats up it expands, causing it to move away from the shoes. This decreases the contact force between the shoes and the drum leading to reduced stopping power. Because the shoes are inside the drum there is less opportunity for the shoes to cool down.

PROS OF DRUM BRAKES

- Lower option price when buying a Truck. S-Cam brakes are more cost-effective initially, making them a more budget-friendly option.

- Service technician familiarity.

- The design is relatively simple, which can make them easier to service/maintain for some technicians.

- Readily available parts (legacy product).

- Multiple configurations (legacy product).

- Brake shoes may last longer than air disc pads.

- Requires lower system air pressure to engage the brakes.

CONS OF DRUM BRAKES

- Inferior performance to Air Disc Brakes due to brake fade and worse if wet.

- Susceptible to brakes fading during heavy use.

- More susceptible to loss of performance when wet.

- Can come out of adjustment.

- Runs hotter due to limited air flow near shoe and hub contact area.

- Brake Drum must be replaced with every brake pad and shoe replacement.

- Brake drums are heavy and hard to handle while servicing brakes.

- Typically, higher overall weight.

- More potential for noise issues.

Air Disc Brakes

Air Disc Brakes were developed in the early 1980s for North American Vehicles, but initial evaluation had issues. Europe started to use them in the early 2000s and has improved their performance so that the majority of all their commercial vehicles utilize them in all positions. A key advantage of Air Disc Brakes is the reduction of brake fade. Because the friction is on both sides of the rotor it cannot pull away from the brake pads as the system heats up. In addition, the rotor has air cooling ports in the center to allow them to run cooler. Any brake fade is a result of the heat build up in the pads during long brake events.

PROS OF AIR DISC BRAKES

- Shorter stopping distance and minimal brake fade.

- More consistent and predictable braking performance, particularly in wet or icy conditions.

- Easier to service – changing out brake pads takes ~50% of time versus drum.

- Depending on application, rotors will last ~200,000 miles with proper preventative maintenance.

- Lower number of major components – Caliper, Rotor, and Hub.

- Runs cooler due to better air flow and vented rotors.

- Calipers have more parts but have higher reliability.

- Lighter weight.

- Less risk of noise issue.

CONS OF AIR DISC BRAKES

- Limited availability for higher capacity rear drive axles.

- Higher initial cost.

Summary

In summary, the choice between air disc brakes and S-Cam drum brakes depends on factors such as the specific application, budget, and performance requirements. Air disc brakes offer superior performance and reduced maintenance but come at a higher initial cost. S-Cam drum brakes are more cost-effective initially but may require more maintenance and provide lower braking performance in some situations.