FAMA BUYER’S GUIDE TC034 APPARATUS MOUNTED WINCHES

APPARATUS MOUNTED WINCHES

Prepared by the FAMA Chassis Subcommittee

This guide does not endorse any manufacturer or product

Contents

Introduction

A winch is a mechanical device used to tension a wire rope and thereby move, lower or hold an object. When developing specifications for a winch for a Fire Rescue vehicle some consideration should be given to what you want to do with the winch. This Buyers Guide provides general information that will help you select a winch for your fire rescue apparatus.

Components of a Winch

Every winch has a drive motor used to power the winch rope in or out. There is also a transmission (or gear drive) and a clutch that engages the winch or allows the drum to free wheel (or spin freely without the clutch). This allows for rapid deployment of the winch rope. The drum is where the winch rope is stored and wound around. There is also a brake, usually located in the drum, which will hold the drum when the motor is stopped.

MOTOR

The winch motor is typically either electric or hydraulic. The motor provides the pull force multiplied through a transmission.

DRUM

The drum is made up of components that correspond with either a wire rope or synthetic rope that should be specified when ordering a winch. Usually, the drum is manufactured for use with either wire or synthetic rope, not both. If synthetic rope is used on a drum manufactured for wire rope, it can crush the drum because it winds tighter on the drum causing cracking or forcing the flanges (sides) off the drum. Only recently, one manufacturer is now producing a drum that can be used for both types of winch rope.

BRAKE

The braking system for the wire rope equipped winch is housed within the drum. If a synthetic rope is stored on this type of drum, the heat created from the drum brake can melt the synthetic rope. The braking system for winches for synthetic rope is located on the outside of the drum, thus eliminating the chance of melting the synthetic rope.

FAIRLEAD

There are two types of fairleads on today’s winches: Roller Fairleads and Hawse Fairleads. The fairlead serves as a guide for the course of running rigging (wire or synthetic rope) to keep it from chafing. It serves as a guide and serves no other purpose. Putting force against it from the winch rope during improper alignment operations can cause failure. A roller fairlead is usually used with wire rope. The opening is surrounded by four (4) rollers, two vertical and two horizontal. It should not be used with synthetic rope as the rope can be caught behind it and either be damaged or broken apart. A Hawse fairlead is used with synthetic rope. Instead of rollers it is a polished aluminum plate with bevels towards the inside of the winch. We have noticed some manufacturers utilizing a Hawse fairlead for wire rope on portable winches. This type of fairlead is made of steel rather than aluminum. You should check with the manufacturer of the winch when specifying on the type of fairlead that they utilize.

Types of Fairleads

Winch Limitations

WINCHES PULL, THEY DON’T LIFT

A winch is geared for hauling or pulling an object on a relatively horizontal or near horizontal plane. Anything pulled above or below 45 degrees from horizontal considered hoisting. Hoisting requires a different type of braking device than is used in a winch. A winch is not a hoist, and you should never use it as such. If you have any intention of needing to hoist, consult with your apparatus manufacturer and specify a hoist rather than a winch.

WINCHES PULL OBJECTS, NOT PEOPLE

Do not specify a winch for any purpose that involves lifting people. The safety factors required for lifting people are much higher than those applied to winches, which are designed for pulling objects. If you need to lift people, do it with an aerial apparatus designed for that purpose.

Specifying Winch Size

WORKING LOAD LIMIT

The Working Load Limit (WLL) is the greatest force that the winch is capable of pulling. The WLL is determined by the rating of the wire or synthetic rope that the winch drum carries. All winch ratings are determined by the tension developed by the first layer of rope on the drum. The first layer is the only layer that will provide a pull equal to the working load limit. The capacity of a winch decreases as more layers are wrapped on top of each other around the drum. Each subsequent layer drops in maximum tension by approximately 10%.

ACCOUNTING FOR SAFETY FACTOR

Since the WLL is determined by the rating of the wire or synthetic rope on the drum, it is important to consider the factors that may reduce the capability of the rope. Wire rope can be damaged by pinching, fraying, kinking, or corrosion. There can be defects in swages, or damage can be caused by hazards at the scene. The same is true for synthetic rope. It is therefore prudent to limit your pulls to a value significantly less than the WLL of the winch. Industry experts suggest that it is good to maintain a 4:1 safety factor in every pull. Using this factor, a 9000 lb winch should be limited to a 2250 lb pull.

STABILIZING DISABLED VEHICLES

Before selecting a winch size, you need to establish what you want to do with your winch. A 4500 lb vehicle can be held on a 30° embankment with the 2250 lbs of pull from a 9000 lb winch while keeping the 4:1 safety factor. A 12000 lb winch could safely hold a 6000 lb vehicle on that same embankment. Figure out what you are willing to do on a scene with your apparatus and select the winch capacity accordingly. Jobs beyond the capability of your winch can be tackled by calling a towing service.

SELF-RECOVERY

If your apparatus will be operating off-road in remote areas, you may wish to consider a winch with strength to assist in self-recovery. The forces required for this are impossible to calculate. The geometry is simple for a vehicle that is rolling if you know the weight and the grade, but if the apparatus is mired in mud, sand, or snow, the forces can’t be calculated with any certainty. In this case, bigger is better.

SAE J706 Rated Winch

The capability of a winch only needs to match the working load limit of the rope on the drum. If a winch is designed in this manner, the winch components only need to survive the forces that the WLL will exert. Some winches, however, are designed to meet the Society of Automotive Engineers recommended practice SAE J706. This standard requires the winch components to be capable of withstanding twice the winch WLL capacity. This provides a 2:1 design factor on the winch components, ensuring that the winch will easily outperform the rope that it is carrying. If you expect to use your winch frequently, you may wish to specify that it be certified as being designed in accordance with SAE J706.

Rope Length Capacity

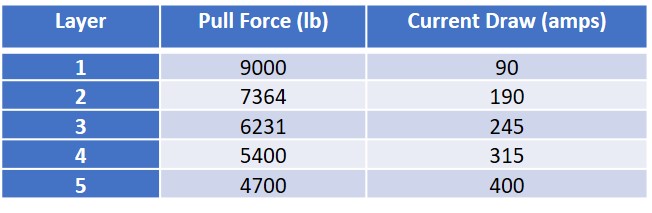

NFPA 1901 requires a minimum of 75 feet of rope for each apparatus winch. You can specify more, but in winch pulls more is not necessarily better. Keep in mind that you to achieve the maximum pull from your winch, you need to pull off enough rope to get to the first layer (that layer closest to the drum). A drum with too much rope will mean that you may not be able to pay enough off before reaching your pull point and you will be winching on the upper layers of the drum. This will reduce your pulling power, and reduce the efficiency of your winch motor. The following example demonstrates how working on the upper layers on an electric winch has less pull but consumes much greater electric power.

12 Volt Electric Winch rated at a WLL of 9,000 lbs.

Direction of Pull

When planning winch operations, it is essential to think about how the apparatus will be oriented with respect to the point of pull. If you will be using your winch to assist in self-recovery, then the direction of pull must be in line with the direction of travel. In this case the winch should be mounted to the front or rear of the apparatus. If you will be using your winch to stabilize disabled vehicles, then it may be more likely your apparatus will be alongside the point of pull and you will want a winch mounted on the side of your apparatus.

One of the roles of winching is to make sure the cable spools up on the winch drum evenly. This is easiest when winching straight forward. If pulled at an angle, the cable is more likely to bunch up on one side of the winch drum. This could result in damage to the rope or drum. Angled pulls may also induce side loads into the winch mount which may result in apparatus damage.

Determine how you plan to use your winch and specify the mounting location accordingly.

Fixed or Portable Winches

Many Fire Departments across the United States have a winch on fire rescue apparatus. In recent years, portable winches have gained in popularity and are usually stored in a compartment and then mounted in receivers at the front, rear or sides of the apparatus.

Fixed – Winches that are permanently secured to the frame of the vehicle. These are usually found on the front or rear of the apparatus.

Portable – Winches that can be carried by 1 or 2 personnel and operated from different receivers placed at the front, rear or sides of the vehicle. The winch is not permanently mounted to the vehicle frame.

When deciding between these mounting methods you should decide how you are going to use the winch. If you are only considering the winch for self-recovery (pulling your apparatus out of a stuck situation), then the fixed winch is appropriate. If you anticipate using your winch to stabilize wrecked vehicles, then a portable winch may be more convenient as it can be positioned to pull off the side of the apparatus.

Power Source – Electric or Hydraulic

Winches can be powered by either an electric or hydraulic source. Power for an electric winch will come from the batteries and the alternator. Power for a hydraulic winch will come from a hydraulic pump, usually driven by a power-take-off (PTO) on the engine or transmission. Here are characteristics of each that you should consider:

ELECTRIC

- Drains batteries if engine is not running

- Easier to install as a portable unit

- Limited run time to avoid over-heating

HYDRAULIC

- Comes in higher capacity ratings (9000 to 30,000 lbs)

- No duty cycle limit

Winch Rope – Metal or Synthetic

Winch rope is the proper name of the cable used on the winch. It is either wire rope (not cable) or synthetic rope. The winch rope is actually the weakest component of the entire system. It is usually rated at, or close to the winches rated capacity. For example, a winch rated at a 9,000-lb. capacity will have the winch rope rated at a few hundred pounds over that capacity. Currently, the exception is on very good quality synthetic rope may be close to 2 times the Working Load Limit (WLL) of the winch. Specifying the quality of rope may not be an option when ordering a winch and may have to be upgraded as an aftermarket item.

WIRE ROPE

Wire rope is currently the more common selection for winch rope. Abrasion resistance and insensitivity to high heat make it the better choice if it will be used around sharp objects or flames. The following are characteristics of wire rope:

- When winching there must be no less than five (5) wraps of wire rope on the drum prior to starting a pulling operation.

- It typically has a Roller Fairlead

- Most portable winches with wire rope will have a steel Hawse Fairlead

- Wire rope is a heavier type of winch rope

- Wire rope stores energy, so if it breaks, the ends will fly in both directions towards the winch and toward the object being pulled

- Metal wire has memory, once damaged it must be replaced

- Not very flexible

- Has good abrasion resistance

- It is resistant to heat

- It is more difficult and cumbersome to re-spool

- Most likely to “bird-nest” when re-spooling

- Damage from exposure to ultraviolet rays is not an issue

SYNTHETIC ROPE:

Synthetic rope is growing in popularity as it is much easier to handle than wire rope and is safer if it fails. The following are characteristics of synthetic rope:

- When using in an operation no fewer than ten (10) wraps must be on the drum to start

- Utilizes a Hawse type of Polished Aluminum Fairlead

- Weighs less than wire rope

- Does not store energy, safer when it breaks

- Synthetic rope does not have memory so it has greater resistance to damage

- More flexible

- Not as heat resistant as wire rope. It melts at approximately 200° F

- Has poor abrasion resistance – must use a protective sleeve on rough surfaces

- It is easier to re-spool

- Less likely to “bird-nest”

- With some brands, ultraviolet light may be an issue (check the manufacturer)

- More expensive than wire rope

Winch Accessories

Your apparatus winch requires some accessories to ensure safe operation. Consider specifying these items along with your apparatus winch.

REMOTE CONTROL

NPFA 1901 states that “Operation of the … winch shall be from a remote location at least 12 ft. from the winch or within an enclosed area.” The NFPA committee recognized that the operator should be a safe distance away from the winch and rope during a pull, or should be protected by an enclosure. A wireless or tethered remote control allows the operator to observe the winch as well as the scene during a pull.

PPE

Protecting yourself and those around you is the first and foremost concern while winching. Winches that have been overloaded, set-up improperly or coupled with unreliable accessories are prone to failure. All personnel attending a winch pull should be in full PPE with leather or rescue gloves.

HOOK STRAP

At hook strap is a length of webbing with a loop sewn into one end. The loop is placed on the hook. It is an essential component for handling of a wire or synthetic rope. The strap is used to hold the hook and keep your fingers from being placed inside the hook and away from the fairleads as the winch rope is deployed or re-spooled back on the winch drum. Always use the hook strap and retain the one supplied with the winch.

SNATCH BLOCK

A snatch block is a pulley block with a side plate that swings open. Because the side plate opens up, it does not have to thread the winch rope through the opening; instead, the side plate opens, the cable fits over the pulley and then the side plate closes. A snatch block has two primary functions in recovery winching. One is to change the direction of the winch cable when the anchor point is offset. The second is to increase the pulling power of the winch.

Ideally, an anchor point would be directly in front of the rescue vehicle, thus eliminating an angular pull. When such an anchor point is unavailable, a snatch block can be used to set up an angled single-line pull.

LOAD SENSING DEVICE

In order to objectively determine the amount of force placed on the winch rope, industry experts recommend the use of a dynamometer or load-gauge in the system where the line is returned from the snatch block back to the apparatus. This device provides the exact amount of tension in pounds of force on the system. The user can pre-determine where the appropriate limit is with the winch and observe it during the operation. This ensures never getting close to the limit of the rope or winch when a 4:1 safety factor is used.