FAMA BUYER’S GUIDE TC041 Hose Restraints

Hose Restraints

Prepared by the FAMA Body Subcommittee

This guide does not endorse any manufacturer or product

Contents

Introduction

Hose restraints have been required by NFPA 1901 since 2009. This safety measure was created following the tragic death of several innocent bystanders that were struck with hose or nozzles that had unintentionally deployed while the apparatus was moving – usually preconnect hose that slid out of the crosslay or speedlay compartment while the apparatus was going around a corner. In other situations, hose has accidently deployed from the main hose bed while enroute to the fire scene. Besides the embarrassment of laying an entire hose load nowhere near the destination, it also creates a safety hazard for traffic.

Overview

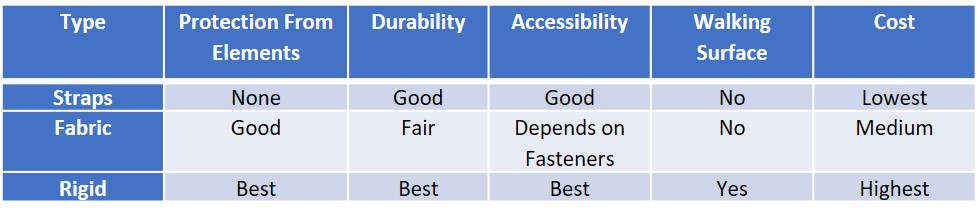

This guide will look at various types of hose restraints and some advantages and disadvantages of each. Hose restraints can be classified by three general types.

- Straps

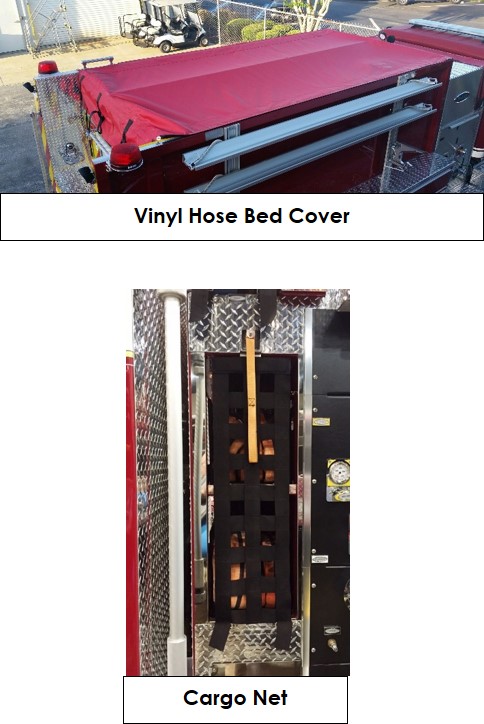

- Fabric covers (vinyl or cargo nets)

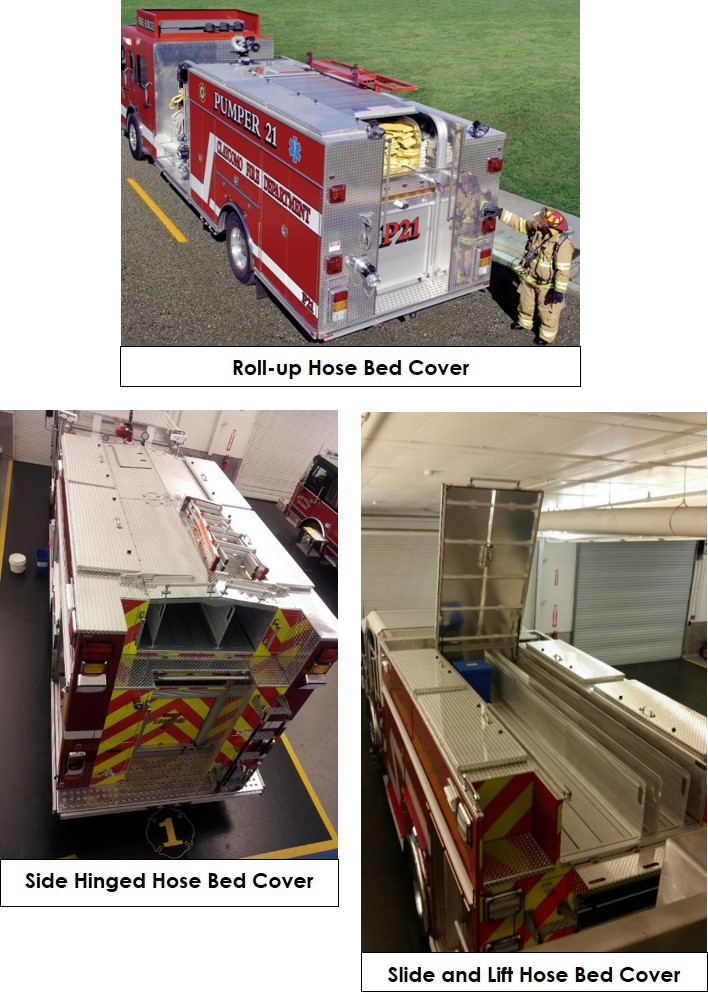

- Rigid covers (treadplate or metal)

Straps

Straps are an economical and simple way to restrain hose stored in a hose well, where hose is contained on all sides but the top. Common applications would be soft suction hose wells in the running board or front bumper hose storage wells. Straps do not work well on open hose storage areas. Straps must be cinched tightly on the hose to prevent sliding out open sides of the hose bed area. The location of the strap tie down points and the possibility of spanning several hose dividers could hinder the ability of the strap to tighten securely on the hose. Straps do not provide any protection from the elements so hose is subject to direct contact with rain, snow, ice or environmental contaminants.

Fabric Covers

Fabric covers and flaps that are usually constructed of vinyl or cargo net material are the most common type of hose restraints. Almost any hose storage area can be contained with fabric covers. Vinyl covers for hose trays, preconnect crosslays and the main hose bed provide hose restraint and protection from the environment. There are a variety of ways vinyl covers can be installed such as bungee cord, buckle straps, twist fasteners, Velcro®, etc. Whatever method is used, the vinyl covers should cover the hose bed area (top and sides) and the cover should be readily removable for easy access to the hose.

Cargo nets are commonly used to secure the sides of preconnect hose storage areas such as crosslays and speedlays. Cargo nets can be used as tail flaps on the main hose bed area when combined with a vinyl or metal cover. Cargo nets are light weight and allow visual inspection of the hose without removing the cover. Cargo nets can be used to cover the main hose load but do not protect the hose from the elements and may be more difficult to secure tightly over the hose bed.

Rigid Covers

Rigid covers generally consist of aluminum treadplate or flat metal material. Rigid covers are almost always used in conjunction with fabric flaps with the rigid cover over the top of the hose and fabric flaps covering the open sides. Aluminum treadplate material with the proper slip resistant rating and support structure can be used as a walking surface over crosslays and the main hose bed.

There are typically two styles of metal covers. Those that are hinged on the sides and open like a clam shell and those that slide and fold up at the front of the hose bed. One other less common design is similar to a heavy duty roll-up door. Metal covers can be manually operated or with power assist such as electric actuators or, in the case of roll-up covers, motor driven. Note that roll-up covers require a large storage area at the front of the hose bed to contain the roller slats when the cover is opened.

In addition to potential walking surface, rigid covers provide enhanced protection for the hose. Rigid covers keep out natural elements and can protect the hose from hot embers that could otherwise damage fabric covers and hose. Rigid hose bed covers provide maximum hose protection and walking surface areas but are also the most expensive solution. Roof top compartments are becoming popular with rescue pumpers. When selecting a hose bed cover, consideration should be given as to how the roof top compartments will be accessed.

Summary

Hose restraints are a requirement of NFPA 1901 and necessary to prevent injury or death if hose is unintentionally deployed. Some items to consider with your hose restraints are:

Manufacturer Contacts

For further information on apparatus and component manufacturers, refer to the FAMA Manufacturers Guide.